deux étapes concasseur de minerai de fer

-

placas de mandíbula Meulage de pierre en la india

-

unite de broyage dans Sahibganj pierre

-

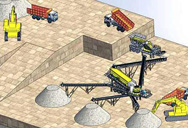

gravel aggregate prodution line

-

minerai entreprises concasseurs finlande

-

matériels de broyage des déchets sanitaires

-

fabricants de broyeurs a boulets dans le Rajasthan 100k

OK™ Raw and Cement Mill - FLSmidth

Vertical roller mill with peak raw, cement and slag grinding performance. Our cost-saving Vertical Roller Mill (VRM) exhibits a modern design approach. We continuously improve our solution with the latest updates to enhance grinding performance and overall productivity.

Bavarder sur Internet

OK™ cement mill The most energy- efficient mill for

2019.4.10 Application advantages. Proven commercially, the OKTM mill is the premier roller mill for finish grinding of Portland cement, slag and blended cements. The

Bavarder sur Internet

Cement mill - OK™ - FLSmidth Dorr-Oliver Eimco

It is affordable to install and cost effective to operate over your cement plant’s lifetime. Vertical roller mill with peak raw, cement and slag grinding performance Our cost-saving Vertical Roller Mill (VRM) exhibits a

Bavarder sur Internet

OK™ raw mill Reliable and efficient raw material grinding

2019.1.24 Parts commonality Operating flexibility Quality and profit-improving features Vertical Roller Mills (VRMs) have been the standard option for raw materials

Bavarder sur Internet

China Vertical Roller Mill, Vertical Roller Mill Wholesale ...

Supplier List Secured Trading China Manufacturer of Vertical Roller Mill Rflm Series Ultrafine Vertial Roller Mill /Grinding Machine/ Mill US $ 5000.0-1500000.0 / Piece 1

Bavarder sur Internet

OK™ mill The most reliable and efficient mill for raw and

2019.4.10 FLSmidth has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades. The

Bavarder sur Internet

OK vertical roller mill - Environmental-Expert.Com

2019.6.29 OK vertical roller mills use 30-50% less energy than ball mill systems Simple layout and fewer machines in the mill circuit ensure high run-factor and low

Bavarder sur Internet

Installed cost comparison for cement grinding systems

2004.4.30 Installed cost comparison for cement grinding systems. Abstract: As the Vertical Roller Mill (VRM) becomes more widely accepted for new cement grinding

Bavarder sur Internet

Vertical roller mill, Vertical roller grinding mill - All industrial ...

vertical roller grinding mill LM series. vertical for limestone for coal grinding. Output: 4 t/h - 300 t/h. ... of advanced technologies of famous international corporations and 30 years’

Bavarder sur Internet

Review on vertical roller mill in cement industry its

2021.1.1 In the study the advantages of vertical roller mill are discussed over ball mills. VRM construction, its process and parameters which affects the performance and

Bavarder sur Internet

quadropol® - thyssenkrupp Polysius

The quadropol® concept for coal or pet coke grinding, with adapted table speed and high efficiency separator sepol®, ensures a safety mill operation and serves reliable the kiln burning process. Mombasa Cement Ltd.

Bavarder sur Internet

OK™ raw mill Reliable and efficient raw material grinding

2019.1.24 The OK™ mill has been FLSmidth’s standard cement VRM since 1993. Since its introduction the OK mill has proven to be the most efficient cement VRM available with the highest reliability and ease of operation. In 2017, FLSmidth introduced the OK raw mill, which is designed with the same proven technology and modular design as the OK

Bavarder sur Internet

ATOX coal mill - FLSmidth

2019.3.18 Today the air-swept vertical roller mill is the standard solution for coal grinding installations. And thanks to our contin-uous refinement of the ATOX coal mill over the years, today’s leading air-swept vertical roller mill is the compact ATOX. Offering high reliability, low installation costs and a wide range of sizes, the

Bavarder sur Internet

Cement mill - OK™ - FLSmidth Dorr-Oliver Eimco - vertical roller / vertical

Vertical roller mill with peak raw, cement and slag grinding performance Our cost-saving Vertical Roller Mill (VRM) exhibits a modern design approach. We continuously improve our solution with the latest updates to enhance grinding performance and overall productivity. The success of the OK™ Mill highlights the reliability of its technology ...

Bavarder sur Internet

外文翻译(中英文)立式辊磨机_百度文库

OK vertical roller mills use 30%—50% less energy than ball mill systems. Simple layout and fewer machines in the mill circuit high run-factor and low maintenance costs. Mill arrangement This schematic illustrates a typical grinding installation。

Bavarder sur Internet

(PDF) Drives for large vertical roller mills - ResearchGate

2017.1.1 10-12. Bo Bentsen. Bentsen, Bo: The unique high energy efficient OK cement mill. Presentation at 20 th Arab International Cement Conference and Exhibition, 10-12. November 2015, Cairo/Egypt. Drive ...

Bavarder sur Internet

Roller Mill Based on Experimental Method - Semantic

2022.4.19 and vertical roller mill i.e., VRM [3–5]. Among these devices, VRM plays an important role in cement, accounting for more than 55% of China’s cement raw meal market [6], and its performance directly affects the cost of producing cement. VRM has the functions of grinding and powder selection, including a grinding unit and an air classifier ...

Bavarder sur Internet

OK Vertical Roller Mill PDF Mill (Grinding) Grinding

2022.4.16 OK vertical roller mill. Quality profit improving features Main features - OK vertical roller mills use 30-50% less energy than ball mill systems - Simple layout and fewer machines in the mill circuit ensure high run-factor and low maintenance costs - Excellent drying capability when grinding blast furnace slag or blended cements with wet

Bavarder sur Internet

Productivity increase of the vertical roller mill for cement

2002.8.6 The specific power consumption, product quality and other performance of the "OK" and "CK" vertical roller mills for cement grinding are briefly stated. Hence, the enhancement in increasing the productivity of the vertical roller mill at Chichibu Onoda Cement Corporation (COCC) is introduced. These include: (a) restoring a table liner and

Bavarder sur Internet

The OK™ mill - the most reliable and efficient mill for...

June 27, 2017. The OK mill has been FLSmidth’s standard cement vertical roller mill (VRM) since 1993. In 2017, FLSmidth also introduced the OK raw mill for raw material grinding, designed with the same proven design as the OK cement mill. The common mill platform implies parts commonality that allows owners to benefit from reduced spare parts ...

Bavarder sur Internet

Review on vertical roller mill in cement industry its

2021.1.1 A two-compartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a true. Vertical roller mill. The feed is ground by pressure and friction between the horizontal rotating table and 4 to 6 grinding rollers in the VRM. These rollers are ...

Bavarder sur Internet

Roller Mill SpringerLink

2023.7.4 Roller Mill. Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table). The roller mill with several grinding rollers as working components rolls along the grinding ring or the grinding table to ...

Bavarder sur Internet

Roller mills: Precisely reducing particle size with greater

2020.11.11 The roller mill minimizes such costs by precisely reducing feed materials with an average particle size up to 3⁄ 4 inch to a uniform average size typically between 100 and 2,000 microns. The roller mill’s ability to reduce materials to a uniform particle size provides more control of product characteristics and minimizes waste, as shown in ...

Bavarder sur Internet

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

2019.4.16 The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operation.

Bavarder sur Internet

Copper ore grinding in a mobile vertical roller mill pilot plant

2015.3.10 Pilot scale vertical roller mill grinding tests were performed for chalcopyrite grinding successfully. ... VRM application is able to decrease the operating costs by about 38.1%. Overall, these improvements can increase the annual income of the plant by 2.2%. ... Operational results of OK series roller mill. IEEE Trans. Ind. Appl., 27 (3) (1991 ...

Bavarder sur Internet

FLSmidth well positioned in competitive VRM market

The average grinding capacity per sale of OK Mills for cement grew by almost 10 % from 2017 to 2018 (206 t/h in 2017 to 225 t/h in 2018). FLSmidth has supplied OK Mills with grinding tables ranging between 2.8 m and 8.1 m in diameter. The number one selling mill size is the OK 56-4 Mill, which is right in the middle of the available size range.

Bavarder sur Internet

Cement grinding - a comparison between vertical roller

2020.3.23 A ball mill with side drive in closed circuit with a high effi-ciency separator enclosed in a building with an installed ball mill power of. 7430 kW and a throughput of 220 t/h. A vertical roller mill installed with a minimum of civil works, i.e. as shown in Fig. 9, with an installed mill power of k and a capacity of.

Bavarder sur Internet

An energy based comparison of vertical roller mills and tumbling mills ...

2015.3.10 The Institute of Mineral Processing at the Montanuniversitaet Leoben in cooperation with the company CEMTEC has developed a pilot scale, 200 mm table diameter, vertical roller mill for energy controlled laboratory tests. The mill provides the technical options to vary process parameters like air-flow, mass flow, grinding force and

Bavarder sur Internet

Efficient machine learning model to predict fineness, in a vertical

2023.3.1 Vertical roller mills are particularly suitable for grinding medium-hard to soft mineral materials, but they can also be used for relatively hard materials. In addition to raw meal and cement clinker grinding, vertical roller mill is also used for grinding phosphate, chalk, etc. ... The cost function to be minimized is [16]: (14) S ...

Bavarder sur Internet

MAAG® GEAR WPU Gear Unit - FLSmidth

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant’s lifetime.

Bavarder sur Internet

Copper ore grinding in a mobile vertical roller mill pilot plant

2015.3.10 A study conducted by Gerold et al. (2012) showed that VRM was able to grind copper and slag with the energy saving of 22.9% and 34.4% respectively compared to conventional grinding circuits. Wear rate is another criterion that is needed to be considered. In this context, Erkan et al. (2012) in their study compared the wear rates of rod-ball ...

Bavarder sur Internet

Installed cost comparison for cement grinding systems

2004.4.30 Abstract: As the Vertical Roller Mill (VRM) becomes more widely accepted for new cement grinding systems differences in installed costs between a VRM and a ball mill system are more frequently discussed. Past comparisons of total installation costs for a ball mill with high efficiency separator versus a VRM have indicated the higher equipment

Bavarder sur Internet

OK Vertical Roller Mill - Free Download PDF - kupdf

OK vertical roller mill 2 Quality profit improving features Main features - OK vertical roller mills use 30-50% less energy than ball mill systems - Simple layout and fewer machines in the mill circuit ensure high run-factor and low maintenance costs - E xcellent drying capability when grinding blast furnace slag or blended cements with wet components -

Bavarder sur Internet

(PDF) Increase productivity of vertical roller mill

2021.1.29 Fly-Ash Blaine: - Increase fly Ash Blaine from 290 to 320. Fly-ash is a major supply for any cement plant now a days because every producer wants to produce. more PPC than OPC due to profitability ...

Bavarder sur Internet

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016.10.5 Vertical roller mills have a lower specific energy consumption than tumbling mills and require less space per unit and capacity at lower investment costs. Vertical roller mills are developed to work as air-swept grinding mills. Roller mills are operated with throughput capacities of more than 300 t/h of cement raw mix (Loesche mill, Polysius ...

Bavarder sur Internet

Productivity increase of the vertical roller mill for cement

1997.4.20 The specific power consumption, product quality and other performance of the "OK" and "CK" vertical roller mills for cement grinding are briefly stated. Hence, the enhancement in increasing the productivity of the vertical roller mill at Chichibu Onoda Cement Corporation (COCC) is introduced. These include: (a) restoring a table liner and

Bavarder sur Internet

Ok Vertical Roller Mill V 3 PDF Mill (Grinding) Grinding

2014.1.7 OK vertical roller mill. Quality profit improving features Main features - OK vertical roller mills use 30-50% less energy than ball mill systems - Simple layout and fewer machines in the mill circuit ensure high run-factor and low maintenance costs - E xcellent drying capability when grinding blast furnace slag or blended cements with wet

Bavarder sur Internet

刷,, ,, α 川 mD e-- dr B司 +L e

2009.11.27 Keywords: vertical roller mill; grinding; simulation 1 Introduction fired power plants and cement plants used 6.16% of all nationwide industrial power-consumption (see Table 1). Statistics also show也at the grinding energy consumption in China was 50%

Bavarder sur Internet

Vertical roller mills: The new leader in grinding technology

2019.10.11 The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the vertical-roller-mill (VRM). For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a new entrant, is still not fully accepted. This is considered a resistance to change

Bavarder sur Internet

MAAG® GEAR CEM Drive - FLSmidth

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant’s lifetime.

Bavarder sur Internet

Articles liés

- broyeur de pierres ligne complète

- rouleaux de broyage xrp943 moulin

- processus de gravier

- combien de tonnes de minerai de fer dans m

- san bao prix Afrique concasseur de pierre

- de concasseur en amérique du nord

- conteneur complet avec du gravier de la calamine

- concasseur à cône primaire d occasion à vendre

- broyage des feuilles de thé vert

- or panoramique concentrateur de tanzanie

- pulvérisateur pour broyeur à Calcite

- portland blast furnace slag cements

- détails de la machine de concassage

- Afrique concasseur de roches brownsville tx

- liste de taux de liming concasseur

- moulin de noyau de dattes

- Taille De La Pierre à Chaux Pour La Centrale à Béton

- ce qui est un schéma de principe dans le traitement des minerais

- dolomite poudre de traitement

- éliminer les contaminants à partir du charbon

- dinde broyeur Indonésie boulets de ciment

- équipement de concassage pour le minerai de cuivre

- concasseur broyeur à boulets

- entretien des moulins à billes dans les cimenteries

- barite processing methods

- los transportadores de mineria a la venta en za

- penurie de sable pour les activites de construction, les etats unis

- Ligne de production de fibres de ciment

- Moulins De Broyage De Carbonate De Calcium Maufacturers

- fabricant de la machine de moulin a main